Batch and continuous fermentation are the two prominent industrial processes. These are generally utilized to produce specific metabolic components, but they vary greatly depending on nutrient supply, types of system, product quantity and quality etc.

Batch fermentation refers to the generation of the desired metabolite in small batches. It is a closed system, and thus the reaction mixture (raw material) and the microbial inoculum are added at the initial stage. On the other hand, continuous fermentation works indefinitely since the raw material and inoculum are consistently fed to the reaction vessel.

In batch fermentation, the product is harvested at the very end of the reaction phase. The product yield is modest, and the product quality differs from batch to batch.

Contrarily, in continuous fermentation, recovers the product continually throughout the process. Although the quantity of the product is relatively large, the quality remains consistent.

With a comparison chart, a brief description, and diagrams, we will attempt to highlight the key points of distinctions between batch and continuous processes in the following content.

Content: Exponential Vs Logistic Growth

- Comparison Chart

- What is Batch Fermentation?

- What is Continuous Fermentation?

- Key Differences

- Summary

Comparison Chart

| Basis of Comparison | Batch Fermentation | Continuous Fermentation |

|---|---|---|

| Meaning | In this type of fermentation is performed in batches where the raw materials and microbial inoculum are introduced at the beginning and product is recovered at last. | Here, the fermentation process is continuously ongoing with persistent nutrient intake and the product is simultaneously recovered during the ongoing reaction. |

| Type of system | Closed system | Open system |

| Application | Suitable of generation of secondary metabolites. | Used for production of primary metabolites. |

| Advantages | • Less labour • Less automation • Only one batch is wasted in case of contamination. | • Highly efficient • Less time consuming • High product yield. |

| Disadvantages | • Less efficient • More time consuming • Low product yield | • More labour demand • High level automation • Huge volume of the raw material and product is wasted if contaminated. |

| Microbial Growth | Microbes are cultivated in the limited supply of nutrients. | Microbes are grown under the constant supply of nutrients. |

| Nutrient supply | Nutrients are added at the initial stage only. | Nutrients are supplied continuously throughout the process. |

| Growth rate | Microbes keep on growing at optimum rate until the nutrients are exhausted. | Microbes grow exponentially with constant growth rate. |

| Growth Phases | Comprise of Lag, log and stationary phases. | Constitutes lag and log phases. |

| Product harvest | Product is recovered after the completion of the fermentation reaction. | Product is continuously discharged during the ongoing fermentation process. |

| Yield | Product yield is low. | Product yield is high. |

| Level of Automation | Can be performed manually and requires less automation. | High range of automation is necessary. |

| Chances of contamination | Low | High |

| Turnover Rate | Low | High |

| Time Duration | Done in 1-2 shifts of 5-7 days based on the desired product. | Requires 24x7 shifts. |

| Internal Changes | Changes as the reaction proceeds. | Doesn't change; Internal equilibrium is maintained. |

| Fermenters | Large fermenters | Small fermenters |

| Initial investment | Low | High |

| Product Quality | May vary from batch to batch. | Remains consistent. |

What is Batch Fermentation?

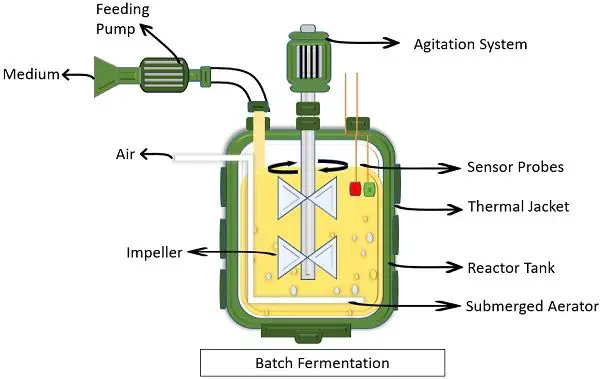

Batch fermentation is a closed culture method in which bacteria ferment the raw material in a batch-wise manner to generate the desired product.

A precise amount of raw material, along with the microbial inoculum, is added to the fermenter and left undisturbed for a set period of time. Following the completion of the reaction, the fermented product is recovered.

Characteristics of Batch Fermentation

- It’s a closed system, which means no material is added or removed during the ongoing fermentation process other than the essential gases, acids, and bases that regulate pH.

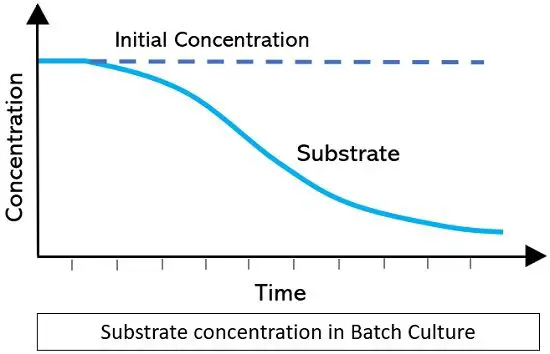

- Microbes consume the provided raw material as the reaction progresses, depleting nutrient volume.

- The internal environmental conditions constantly fluctuate due to reasons such as raw material shortages, increased product production etc.

- Nutrients are only given as the reaction starts and are never supplemented while the reaction is running.

- The utilization of the nutrients by the microbes is relatively slow, resulting in a low response turnover rate.

- The fermenter is cleaned and washed after every subsequent batch.

- Batch fermentation is simple to set up and manage since it does not require a high level of automation or technology. This reduces the cost of investment and maintenance.

Diagramatic Representation of Batch Fermenter

Microbial Growth Curve

The microbial inoculum begins to modify themselves to begin division as soon as they are introduced into the raw material and the proper environmental conditions are provided.

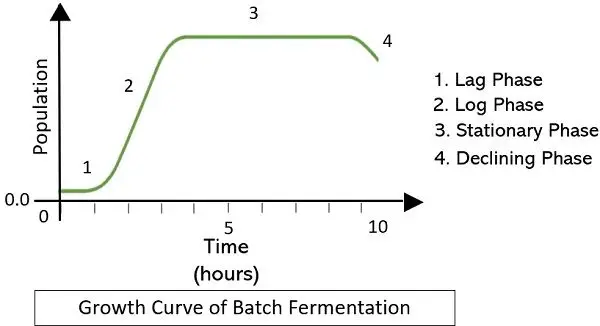

In batch fermentation, the growth curve clearly illustrates four distinct phases:

- Lag Phase: During this phase, bacteria grow in size and increase cellular components in preparation for division.

- Log Phase: This is the most essential phase, during which the microbes multiply to their full biotic potential by utilizing the nutritional supplies available to them.

- Stationary Phase: This phase begins when the nutrients run out, and the competition for survival heats up. As the birth rate equals the death rate, the growth curve flattens.

- Declining Phase: As the nutrients are exhausted, the microbial growth rate gradually reduces to generate a declining curve.

Application of Batch Fermentation

Batch fermentation is used for fast and limited product yield. Prevalent for production of the secondary metabolites. For example, antibiotics like penicillin etc.

Advantages of Batch Culture

- Easy to set up due to lower investment cost

- Automation and machinery requirements are reduced

- Lesser chances of contamination as it is a closed system.

- Less labour is needed due to the simplicity of the process.

- In case of contamination, only one batch is wasted.

Disadvantages of Batch Culture

- As a considerable portion of the product is combined with cellular debris and waste toxins, the product yield is reduced.

- The turnover rate is relatively low.

- Lesser productivity time.

What is Continuous Fermentation?

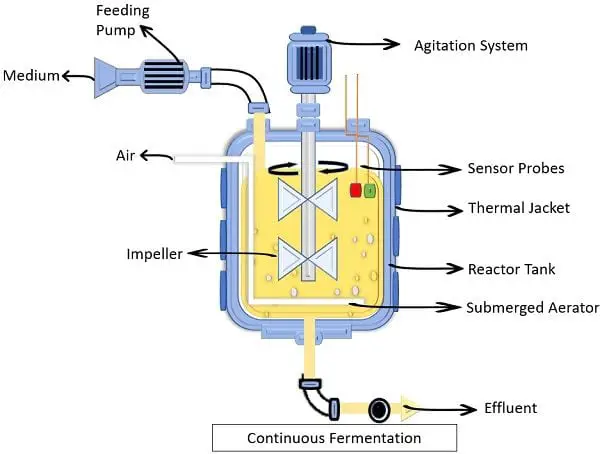

Continuous fermentation is an open culture approach. Here, nutritional supplies are continuously provided, and the product is continually withdrawn during the ongoing fermentation reaction.

Because of the steady supply of raw materials, the microbes proliferate exponentially. The microbes reach their full biotic potential due to the abundant supply of nutrients.

The characteristics of the Continuous Fermentation

- It’s an open culture system in which nutrients are added simultaneously as the product is removed. This creates a state of equilibrium in the system.

- The internal environments always remain constant due to this equilibrium.

- Because the product is isolated directly from the overflow or bottom product recovery channel, the contents of the fermenter vessel are never entirely emptied.

- The nutrients are relatively utilized faster, resulting in a high product yield.

- As the substrates are exponentially converted into the product, the turnover rate is very high.

- A high level of automation and machinery is necessary.

- The system requires a significant amount of investment to set up and maintain.

- Because of the continual food intake, the fermenter is never cleaned or washed before the subsequent fermentation operations.

Diagramatic Representation of Batch Fermenter

Microbial Growth Curve

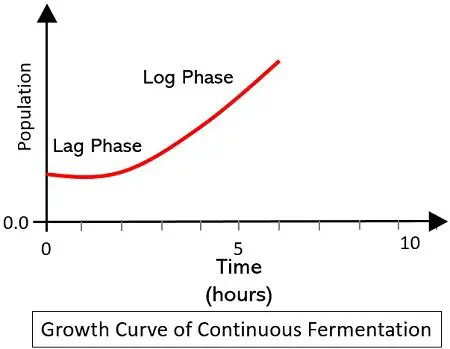

The microorganisms in continuous culture are always in active division phase, consuming raw materials on a regular basis. As a result, they increase exponentially, resulting in a J-shaped curve.

It only consists of two phases:

- Lag Phase: When nutrients and inoculum are mixed at the start, the cells adjust to the division by growing larger and changing their cellular makeup. The microbes proliferate exponentially once they have passed through this lag period

- Log Phase: The microorganisms grow at their maximum biotic potential during this phase by utilizing the continuous medium supply. This is the ever-lasting phase in the continuous culture.

Because microbial growth is never diminished due to nutritional deficiency or nutrient competition, the stationary and decreasing phases are absent in continuous fermentation.

Types of Continuous Culture

There are two types of continuous culture techniques:

- Turbidostat: In this, the turbidity or the optical density is measured as per the cell count. The turbidity level is used to track the amount of nutrients added and products removed. It necessitates the integration of a real-time feedback sensor.

- Chemostat: This method is used to grow the microbial cells continually in any specific phase of growth. A portion of the product containing actively diving cells in a specific phase is always left in the fermenter during product recovery. This serves as an inoculum for the nutritional supply to come. The microorganisms’ desired stage is constantly maintained in this sort of fermentation.

Applications of Continuous Fermentation

It has only a few industrial applications. Primary metabolites are the main products of this process. Single-cell proteins (SCPs), for example.

Advantages of Continuous Culture

- A higher rate of turnover.

- Increased productivity.

- Highly efficient and saves time.

- It cuts down the extra time for cleaning and washing the fermenter vessels.

Disadvantages of Continuous Culture

- Higher initial investment is required.

- High-level machinery and automation are needed.

- In case of contamination, a large volume of the raw material, as well as product, is lost.

Key Differences Between Batch and Continuous Fermentation

- It is a fermentation where the microbes perform the fermentation in batches of the provided raw material. Contrarily, in continuous fermentation, microbes ferment a continuous supply of nutrients.

- Batch culture is a closed system in which nutrients are only provided at the start of the process and never during the process itself.

In contrast, continuous fermentation is an open system in which nutrients are continuously provided throughout the fermentation process. - In batch culture, the turnover rate is low because the bacteria absorb nutrients slowly. However, in continuous culture, the microorganisms rapidly consume the raw material, raising the turnover rate.

- The product yield is low in batch fermentation and is comparatively higher in continuous fermentation.

- The product is only retrieved when the batch culture fermentation process is completed. In continuous fermentation, the product is simultaneously withdrawn during the ongoing fermentation.

- Batch fermentation is simple to set up since it involves less automation, a smaller workforce, and is less challenging to manage. As a result, it has a cheaper investment cost.

- On the other hand, continuous fermentation necessitates a high level of sophistication, automation, and technology. This raises the investment cost.

- Chances of contaminations are low in the case of batch culture as it is closed in nature. The continuous culture has a greater risk of contamination as it is an open system.

Summary

Both the fermentation techniques- Batch and Continuous are equally crucial in the industrial sectors, but their use might vary as per the desired product.

The batch fermentation generates the fermented product with a fixed amount of nutrients and inoculum for a set period of time. However, as the nutrient quantity depletes, it becomes a limiting factor for the microbes. Thus, their growth ceases as the raw material is exhausted.

Continuous fermentation is an open system with an unlimited and constant supply of raw material. The actively dividing microbes over exponentially as the nutrients never become a limiting factor.

Leave a Reply